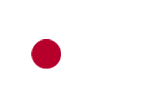

Thanks to nanotechnology, the photovoltaic film designed by Ribes Tech, is printed on lightweight and flexible plastic sheets capable of transforming solar and artificial radiations, such as light bulbs, into electricity, powering home automation systems and other technologies.

This is an effective solution both for saving money, because it reduces the need of using batteries and for the protection of the environment. As a matter of fact, unlike normal batteries, this photovoltaic film can be recycled as any plastic compound.

Ribes Tech is a start-up, founded in March 2016. It is the result of the partnership between the “Italian Institute of Technology” (ITT) of Milan and the OMET of Lecco. The first is specialized in nanotechnology, while the second is forefront in the construction of machinery for printing.

Such a combination of industrial and scientific skills was strongly desired by Marco Carvelli, a 30 years old physics engineer graduated from the Polytechnic University of Milan. After his journey in Holland, he is now back to Italy, where, together with other researchers, whose age does not reach thirty-five, is working on a cutting edge project on photovoltaic panels. This innovation is put into practice by laying the so-called pioneer inks, for printing.

The idea of Ribes Tech started with the study of Oled, i.e. diodes (devices that emit light) on modern computer monitors and mobile phones. The photovoltaic cells of the Ribes Tech project are very similar. The only difference is that rather than emitting light, they absorb it and transform it into electric energy.

What is the photovoltaic Ribes Tech Film?

image credit: Ribes Tech

Ribest Tech, the start-up designed and conceived by Carvelli, has invented a photovoltaic film capable of powering home automation systems and other technologies.

This film is printed on plastic sheets at a very low cost and in large volumes and works with artificial light. These sheets are very light, thin and flexible. The main feature of this production technique is to be able to lay, while printing, semiconductors and conductors materials which give shape to a photovoltaic cell. The materials used are dissolved in suitable solvents to produce special inks. These inks are compatible with the rotary printing technique, the same technique used for printing newspapers, paper handkerchiefs, and labels for bottles. The film is printed on cheap layers of different colors and shapes that meet the needs of the various environments.

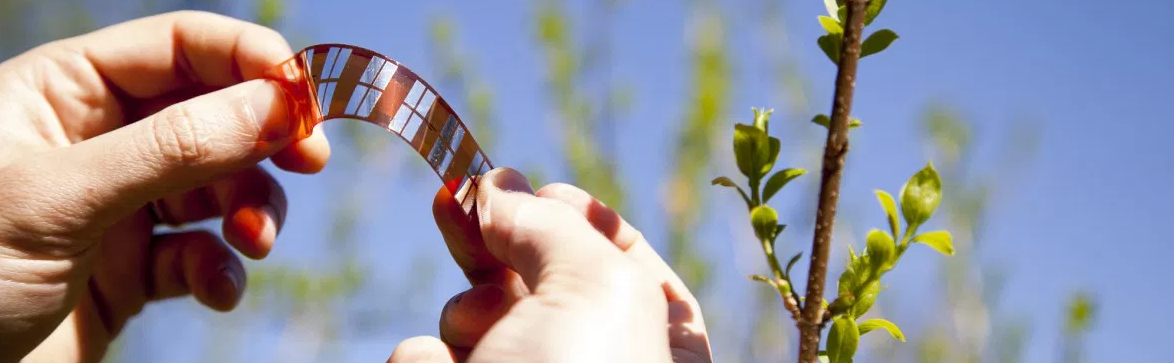

How does the photovoltaic film by Ribes Tech work?

image credit: Ribes Tech

More specifically, this is how it works: the photovoltaic cells use a semiconductor polymer mixed with fullerenes, i.e. carbon nanospheres. This compound is laid on a plastic sheet.

The sheet is like a double sandwich: at the bottom, on a plastic layer, a stratified cell is printed, and then covered with another plastic sheet. Such a process is possible with the help of nanotechnology: this technology allows materials being handled at molecular levels and transforms them into a sort of ink, which will be subsequently printed on the film. Once the ink is dry, these nanoparticles will transform solar radiation into electricity.

PET is the support on which these cells are printed, i.e. the same plastic used for making water bottles. Many different layers, related to organic semiconductor materials, are laid on this film. We are talking about special polymers, or plastics, which act as electrical semiconductors or conductors. Thanks to these polymeric materials, this photovoltaic film that powers home automation systems, doesn’t release any toxic substances. Moreover, this product is suitable for the disposal and the recycling of normal plastics.

Features and advantages of the photovoltaic film by Ribes Tech

image credit: Ribes Tech

This photovoltaic film does not only perfectly work with artificial light, but it is even more powerful than other technologies such as silicon panels which can normally be seen on roofs. This occurs because the film can be easily replaced, by changing the portion of light absorbed by the cell. It goes without saying that artificial light conveys less energy compared to solar light. Very often, artificial light is what is more than enough to power home automation systems and the so-called Internet of Things “IOT”.

The photovoltaic film by Ribes Tech with artificial light has more or less the same life of batteries. It can generate a few tens of microwatts per square centimeter. Thanks to these sheets, it is possible to reduce the use of batteries, saving money, while having a great advantage for the protection of the environment. Batteries contain some toxic substances and sometimes it is hard to dispose of them properly.

The film, instead, at the end of its life, can be recycled as any other plastic compound.

It is still very difficult to give an estimated price of these photovoltaic sheets that power home automation systems. Probably, in the future, such films will have the same price of a simple bottle label. At the moment, however, there aren’t many companies that produce the inks required for manufacturing these photovoltaic layers. That is why, small groups of researchers are producing these inks in smaller quantities, but not in an automated manner. In this way, unfortunately, costs are still high, but should not be higher than the cost of an AA battery.

The target of these researchers is to use the photovoltaic film within home automation systems such as for sensors, temperature and alarm detectors, remote controls, electronic labels and displays. However, in the future, the target is to use this technology for mobile phones and electronics in general.

The purpose of Ribes Tech

The purpose is also to enter into agreements with companies specializing in home automation, wireless, sensors, networks and electronic systems. The purpose of Ribes Tech is to collaborate with these organizations, as they might be potentially interested in using these photovoltaic modules for their production.

Ribes Tech has been dealing for a while with a project related to the creation of a photovoltaic film, mainly in the home automation industry. Many prototypes were developed, but soon, during the year, business partnerships will be signed representing a vital part for launching this product on the market.

The idea of Ribes Tech start-up is to collect all these things that are wasted daily, and that we don’t even realize that we are wasting. Before the age of nanotechnology, no one would have ever thought that we could achieve flexible, light, very thin photovoltaic modules, capable of transforming light bulbs into electric energy.

We just have to wait for the evolution of this proudly Italian project, which will lead our country (and not only), to produce and consume a more sustainable energy.

The photovoltaic films by Ribes Tech have been recently awarded by the “Mit Technology Review”, as one of the ten most important innovations designed in Italy from people under 35.