news lato slider (EN)

Just browse through our LTC catalogue to see that there are dozens and dozens of Halogen-free cables in our offer, daily requested by wholesalers all around the world. But where does their real need come from? In this article we want to make a bit of history and an analysis of the current market since, even at this time, the Research and Development department of La Triveneta Cavi is focusing on the design of new CPR Halogen Free cables to ensure more and more security in high-density people buildings.

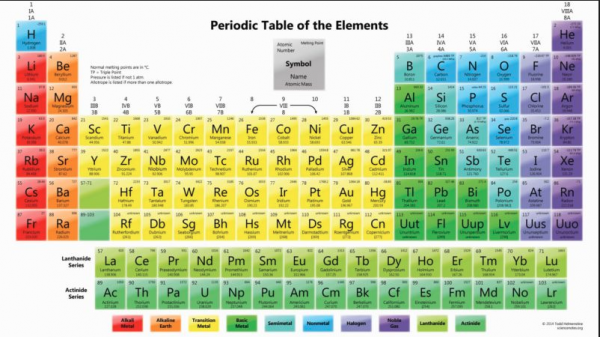

Identifying Halogen elements

The Halogens, or elements of group 17 of the periodic table, are Fluorine (F), Chlorine (Cl), Bromine (Br), Iodine (I) and Astate (AT). Halogens react with almost all elements of the periodic table and form ionic or covalent compounds that are often used as starting materials for the synthesis of other compounds, both inorganic and organic. Among the applications there is also the production of insulating material, used in transformers and, of course, in electrical cables.

Hazard of halogen elements in cables

Halogen elements, under certain conditions, can promote the spread of a fire and the gases released may cause serious damage to health. In excessive quantities, halogens have an immunosuppressant effect and weaken people’s cognitive and coordination skills.

Historical notes on the hazardousness of halogen elements in electrical cables

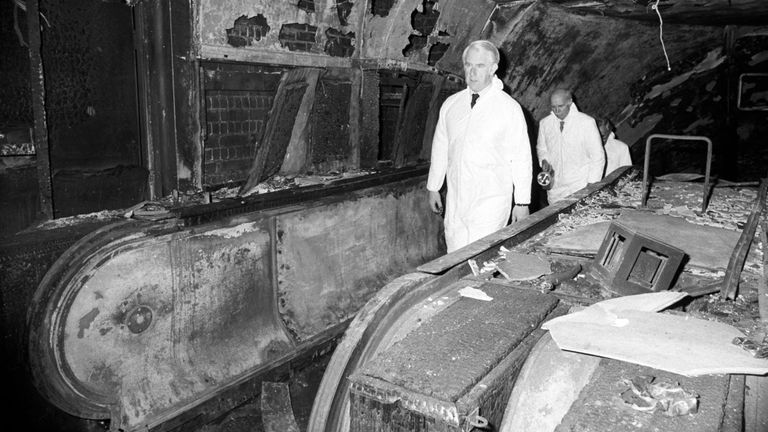

According to the well-informed blog www.incore-cables.com, the key event that brought out the danger of halogen elements in power cables was the fire at Kings Cross station in London in 1987. In that catastrophe 32 people died and following investigations showed that the majority of deaths were due to the toxicity of gases and smoke, emitted by electric cables and inhaled by people, rather than to burns or open flames. That was the only time that people died in a fire in the London Tube.

Mandatory use of Halogen Free Cables

As a result of the fire at Kings Cross station, companies, cable installers and safety experts decided not to manufacture or use any more cables containing halogen elements. Soon came the obligation from the authorities that was extended not only to the London Tube and to other stations in general, but in all those buildings or infrastructure, public, private and high-density people, such as cinemas, shopping malls, hospitals, offices, etc..

Continuous development of Halogen Free cables

The obligation to install Halogen Free cables arisen after the metro accident reinforced the growing attention to safety and therefore, in the following years, La Triveneta Cavi began to produce the first LS0H (Trisecur) cables. The recent process of improving safety has seen the entry into force of the CPR Regulation (2017). Triveneta Cavi has already developed over 90 families of cables certified according to the CPR regulation and continues to develop new ones. Soon we will announce the launch of new Halogen Free cables that, completing our wide range, will add to all the others already in the catalog.

The brand La Triveneta Cavi was the protagonist of the recent Winter Olympics in South Korea 2018 which ended about a year ago.

Thanks to our Dubai partner Cleveland Cable, 250 Km of H07RN-F cable, manufactured at our La Triveneta Cavi facilities, were used to supply power to the entire Winter Olympic sports complex in Pyeongchang County, 180 Km from the capital Seoul.

Cleveland Cable recently told us about the success of such a big operation, starting with an auction that required a single cable supplier. The winner was our H07RN-F: it is a cable with excellent flexibility and good resistance to abrasion and tearing; it is resistant to weathering, grease and oil. It can be used both indoors and outdoors for mobile laying and ensures functioning down to -40°C, which is very important as these are winter sports games where snow and ice are the main element.

After the production that took place quickly and smoothly, the containers of material traveled directly from Italy to Dubai, where our partners worked with skill and precision in order to assemble cables and connectors under the instructions of their customers. The customer’s orders were very restrictive not only in the design phase but also as regards timing and shipments. The work table, in fact, required Cleveland Cable to supply the cable in very precise quantities and timescales and in steps. Furthermore, the budget and the estimated costs have always been respected, meeting the satisfaction of the final customer and, above all, the perfect success of all the installations of the 2018 Winter Olympics.

La Triveneta Cavi is very proud to have supplied its own product, designed and manufactured entirely in Italy for the realization of this great work of international scope and that has given us great visibility and prestige in our industry. We congratulate our partner Cleveland Cable and we look forward to the next major projects that await us in the world.

In addition to mechanical and electrical tests, cables are often also subjected to fire tests (the CPR Regulation is proof of this). The most common test is the flame retardancy. In fact, each cable sold must comply with certain resistance standards that vary according to the country of installation.

In the video we made at the laboratories of La Triveneta Cavi, we illustrate two ways to carry out the test, but according to different countries that require different requirements of the test: the one in force in the European Union, EN 60332-1-2 and the one used for North America, UL 2556.

Both have the same purpose but different methodology. In the European test EN 60332-1-2 the cable must be subjected to a continuous flame for a time determined according to the diameter of the cable. In the American test EN 60332-1-2 instead, the cable must undergo a series of cycles where the flame is applied and then removed.

Both cables tested have successfully passed the two tests; it is very interesting to visually observe the exceptional performance of the FG17, designed to withstand in these harsh conditions with a very low flame propagation.

From 2017 onwards safety has become, in the complex world of electrical installations, the main focus.

The Decree Law No 106 of 16.06.2017 has set a clear condition on the use of cables in accordance with the CPR regulation. La Triveneta Cavi has promptly responded to this change and is now providing, in compliance with the standards, a cable suitable for all plant situations.

In the circular of December 14, 2018, the IMQ officially announced the repeal of the Technical Specifications IMQ-CPT-007 relating to FROR cables (shielded and unshielded):

FROR 450/750 V or FROR 300/500V (shielded version)

FROH2R 450/750 V or FROH2R 300/500 V (braided shielded)

FROHH2R 450/750 V or FROHH2R 300/500 V (AL / PET + braid)

FROH2R 300/300 V

The IMQ’s decision to make FROR cables obsolete puts an end to their widespread use, which is not completely covered by installation regulations.

FROR cables were designed for mobile use, for indoor environments and for temporary outdoor use. However, they were normally used for fixed installation inside buildings and, while taking the appropriate precautions, they were also used for fixed laying rather than for underground laying.

What are therefore the main changes for designers and installers?

1. As a consequence of the IMQ’s repeal of the IMQ-CPT-007 Technical Specifications, from August 2019 FROR cables will no longer be able to be manufactured with the quality mark.

2. It has been a while since La Triveneta Cavi started managing its stock in the warehouse and designed new cables that fully meet the following requirements and technical regulations:

FS18OR18 cables for sections up to 2.5 mm² for voltages up to 300/500V (Cca-s3, d1, a3)

FG16OR16 cables for voltages up to 600/1000V (Cca-s3, d1, a3)

3. The conditions of use of these cables and their laying procedures will be indicated in the CEI 20-40 cable guides and in the Standards for Electrical Installations, CEI 64-8.

Interview to Mr. Matteo Caldognetto, Sales Export Manager of La Triveneta Cavi.

In which markets are LTC cables present?

The export market represents more than 70% of LTC’s turnover, since we are present in over 40 Countries worldwide. Over the past 5 years we have seen a constant rising on the export sales with a 60% increase from 2013 till 2018. This was possible thanks to the efforts of all our Area Managers, back office operators and all other LTC departments.

What are the emerging areas for LTC market?

Germany remains the main European market but we are also focusing on other markets , like Scandinavia, Eastern countries and Russia. Worldwide, South America is facing a positive trend, last year we signed an important agreement with Mexico and we keep developing new business with other important dealers in those countries, as well as Africa and South East Asia.

How is the Made in Italy product perceived?

It is very positively perceived. We receive many inquiries from countries which are installing high quality Italian machinery and they also need Italian cables to have all the characteristics and certifications that our market guarantees.

What are your goals for the immediate future?

To confirm our very good sales in Europe and develop all other non- EU countries where we are not present yet but that require high quality products and a flawless service.

What’s this year’s most important news about La Triveneta Cavi?

LTC has invested several millions by realising a new automated Logistics Center that brought many advantages for the customers in terms of fast deliveries and precision. We are able to load and despatch 30 trucks per day and we have improved also the quality of the service through an automated management of the delivery.

La Triveneta Cavi has been awarded the “Company to Watch” award for 2018 as part of the Databank analysis of the Cables and insulated conductors’ industry.

Take a look at the preview of the official inauguration of our new automated Logistics Centre that took place last Saturday October 20th at our premises in Brendola.…Read more

On 11 and 12 October, we have the pleasure of meeting this group of EVENTUS electricians (Slovenia) to show our production facilities in Brendola (Vicenza).…Read more

A key event for professionals in the electricity sector, in energy efficiency (and related solutions), in plumbing and heating engineering. This year, Rexel Expo will take place on 3 and 4 October in Parc des Expositions Lyon Eurexpo.