Highlights

According to the 2019 statistical yearbook of the National Fire Brigade, in 2018, about 58,000 fires took place in Italy in environments affected by the CPR regulation.

SCHOOLS: 2208

RESIDENTIAL HOUSES: 53648

COMMERCIAL ENTERPRISES: 2144

These data are available in the 2020 edition of the CPR guide of AICE ( Italian Association of Cables and Electrical Conductors) entitled: CPR, The new Cables Age. The numbers make us understand the importance of safety in buildings in case of fire.

This document, addressed to project designers and installers, is an update of the complete guide to the Construction Products Regulation applied to Electric Cables and explains, among other things:

– the legislative scenario;

– the economic operators in the supply chain;

– the requirements imposed by the CPR regulation;

– Marks and Markings

AICE’s CPR guide is available in PDF at this link and in the Download area of our website www.latrivenetacavi.com.

La Triveneta Cavi and AICE

AICE, which La Triveneta Cavi has always been linked to, is an association of FEDERATION ANIE (National Federation of Electrotechnical and Electronic Companies), which in turn is part of Confindustria, and represents companies active in the energy cables and accessories, communication cables and electrical winding conductors sectors.

AICE member companies are 39 (for a total of 7,000 employees) and in 2019 they had a turnover of about 3,000 million Euros.

AICE guarantees its members a continuous update on the evolution of the European Directives in force and under development (LVD – Low Voltage Directive; EMC – Electromagnetic Compatibility Directive; CPR – Construction Products Regulation; etc.).

In particular, with reference to the CPR Regulation, AICE member companies have focused their investments on research and development of safe and reliable products to be used in applications where the health of people and the protection of things must be guaranteed in case of fire.

Video presentation FTG18 Trisecur Top cable with flame resistance test explained by our technicians.

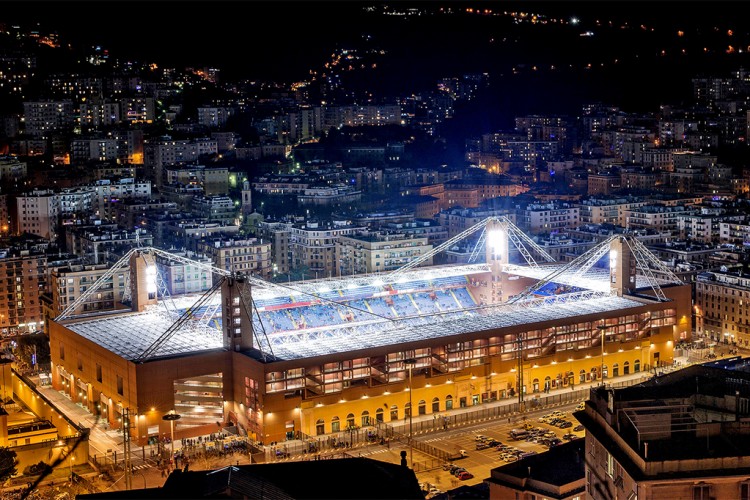

After the Dacia Arena in Udine (one of the most innovative sports facilities in Italy), even the energy of the Marassi stadium in Genoa, starting from the current football season, is flowing through electric cables produced by La Triveneta Cavi. In fact, for the recent restyling of the famous Ligurian stadium, a large supply of our cables has been selected. The Luigi Ferraris Stadium is 110 years old and is the oldest football stadium still working in our country, recognized as one of the sports facilities that has made the history of Italian football. In 1933, between the two wars, it was named after Luigi Ferraris, captain of Genoa who died in the First World War.

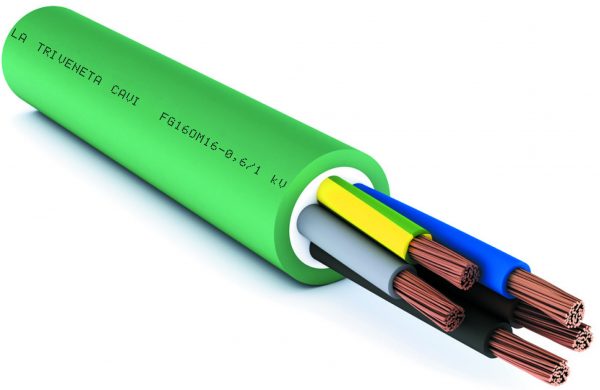

Trisecur FG16OM16, a perfect cable for Stadium Marassi

27 kilometers of BT Trisecur FG16OM16 10G2.5 produced by La Triveneta Cavi were used in the works for the new lighting system of the stadium, mainly employed to power the lights and the safety lamps arranged on the entire surface of the stadium. Our Trisecur cable offers maximum safety and is in fact required by designers of sports facilities as it is resistant to weather and variable temperatures, with a guarantee of functioning for many events to come.

As reported by the website Calcio e Finanza – there is a project worth over 40 million euros to be implemented over the next three years.

The project includes the construction of a “sky box” area with luxury lounges dedicated to companies and sponsors, the renovation of the changing rooms, the construction of a conference center, entertainment areas, restaurants and shops.

For this facility Forum LED projectors (by Disano illuminazione Spa) were chosen, the spotlights that have brought the quality of LED lighting up to the level of large sports facilities. In addition to energy savings, the perfect stability of the light, with high color rendering, guarantees high-definition TV shooting and maximum comfort for both players and visitors.

The new Luigi Ferraris stadium system includes 240 1392W Forum LED projectors with 3 different optics, replacing the 368 old generation 2000W lights.

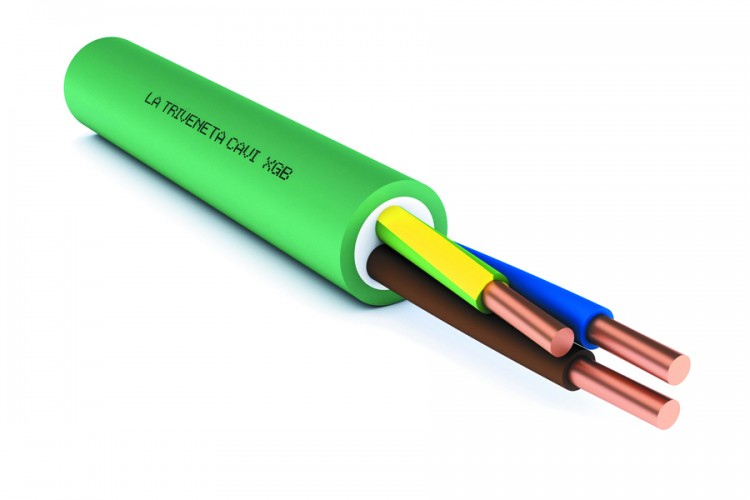

About 175 kilometers of FG16(O)R16, H07RN-F, FS17 (for a total of 215 tons) designed and manufactured by La Triveneta Cavi have been purchased and will be installed by our African partners Elektrint Nigeria Ltd. for the construction of an impressive new production site Nigeria, on a plot of land of more than 16 hectares.

With the construction of the new plant, the completion of which is taking place in these days, the company will become the largest producer of BOPP + BOPET films on the African continent; for their processing the company uses advanced technology managed by the French group ESOPP.

Given the scope of the project and the structure of this impressive construction, the cables required must ensure considerable energy flows and a high level of safety (important cable sections). The project was followed by our partners Elektrint Nigeria Ltd, specialized in Electrical and Hydraulic Engineering, Air Conditioning, Pipelines and Fire Protection, Surveillance Systems and Pre-Fabricated Structures, operating in Africa for over 36 years, who have chosen to use the CPR cables of La Triveneta Cables, which meet European regulatory requirements, the highest and most restrictive in the world. The choice to use the Italian cables of La Triveneta Cavi, recognized in the selection phase as the ideal product, brings to our company a great prestige and allows us to further expand our brand on the African continent that in the future is the one with the greatest margin of development in the coming years.

Here are the three types of cable used for the system:

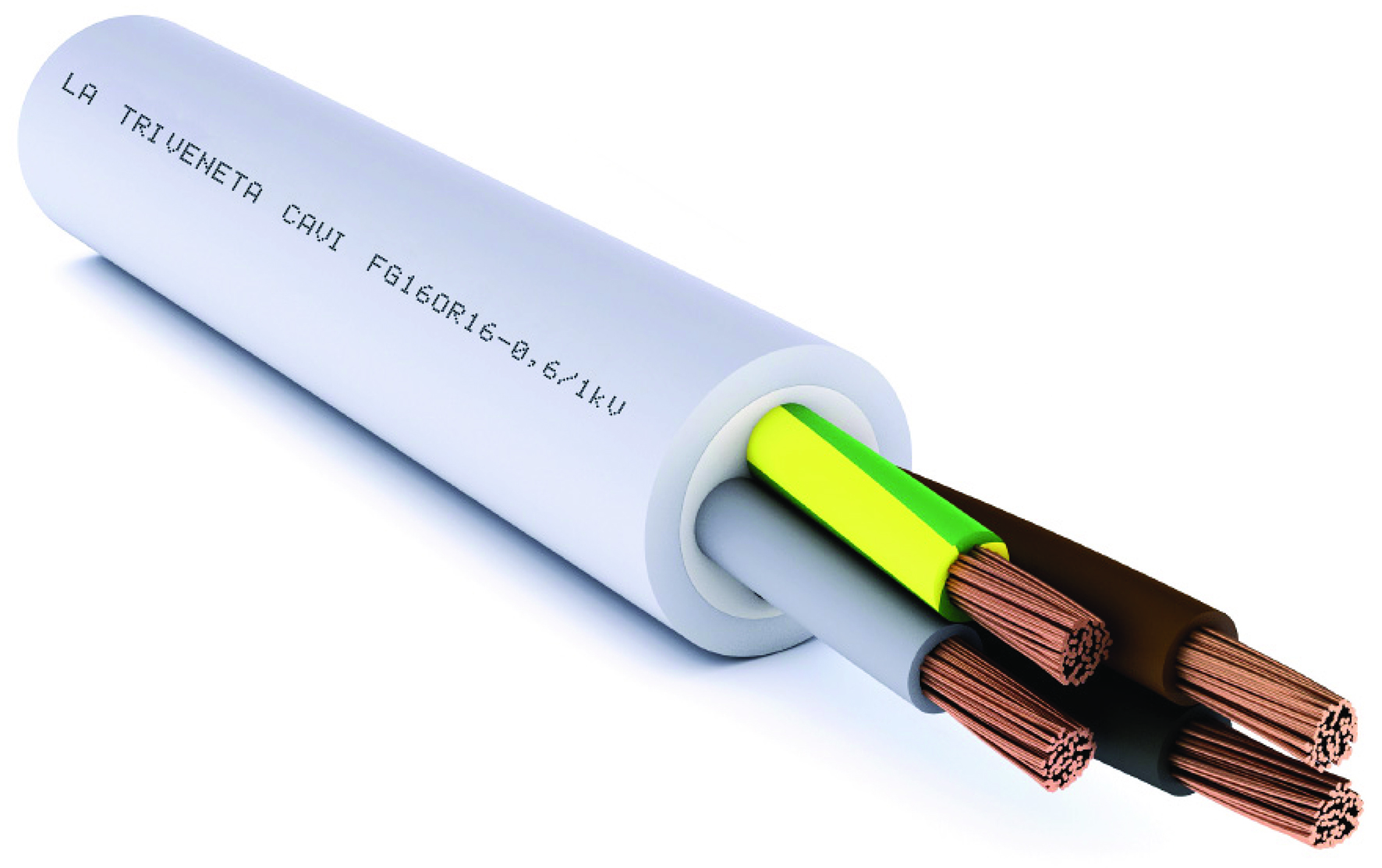

FG16(O)R16: Used for fixed installation in industry and construction sites, suitable for outdoor, indoor, on metal structures or in the open air, can also be used in damp environments and at risk of fire. Good ability to prevent the spread of fire.

H07RN-F: Used mainly for mobile installation in indoor or outdoor environments, to supply energy to machinery and equipment for the construction of infrastructure. Much appreciated for its excellent resistance to mechanical stress.

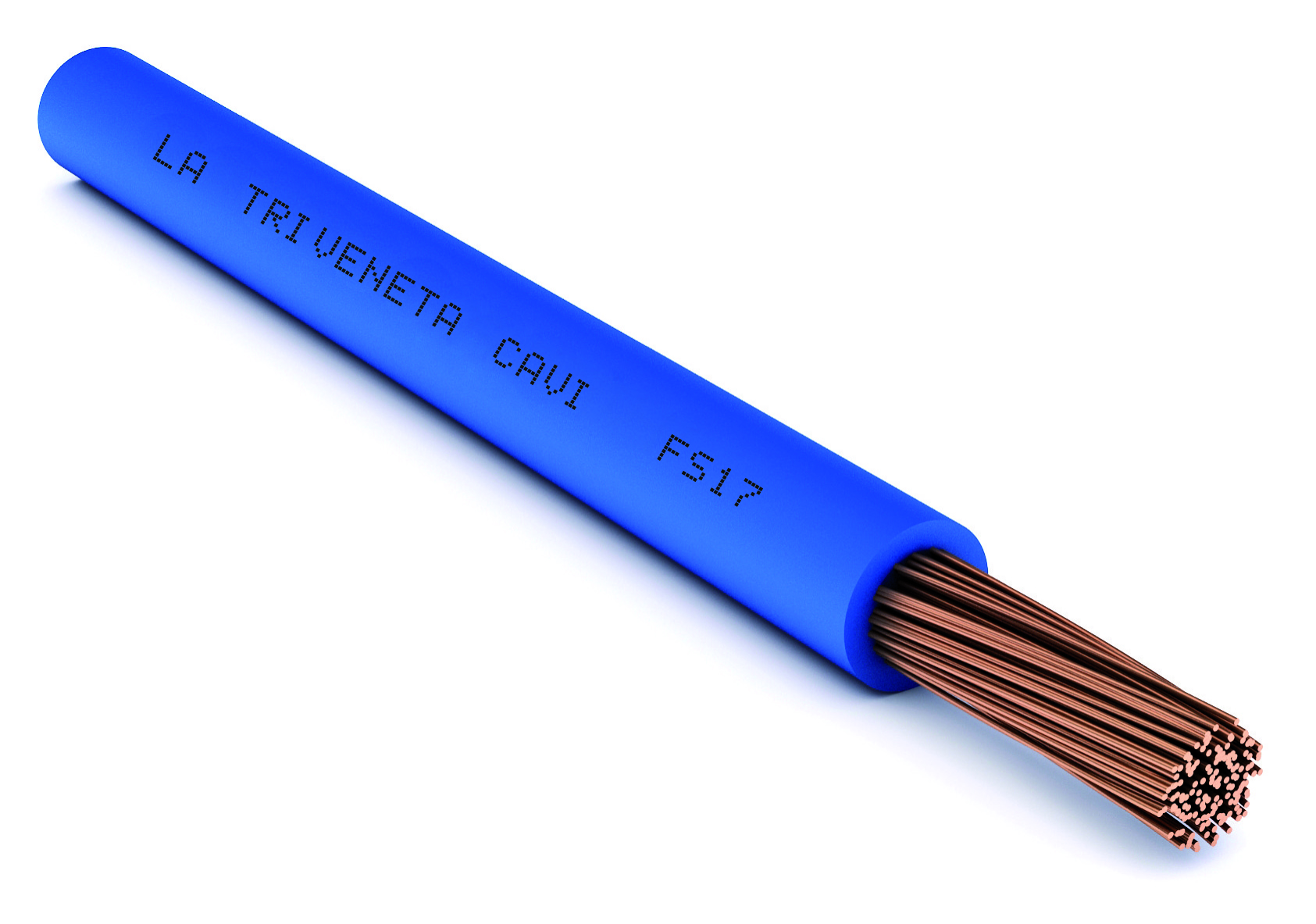

FS17: Used for fixed installation inside ducts and pipes inside buildings, for lighting and power supply in offices.

Just browse through our LTC catalogue to see that there are dozens and dozens of Halogen-free cables in our offer, daily requested by wholesalers all around the world. But where does their real need come from? In this article we want to make a bit of history and an analysis of the current market since, even at this time, the Research and Development department of La Triveneta Cavi is focusing on the design of new CPR Halogen Free cables to ensure more and more security in high-density people buildings.

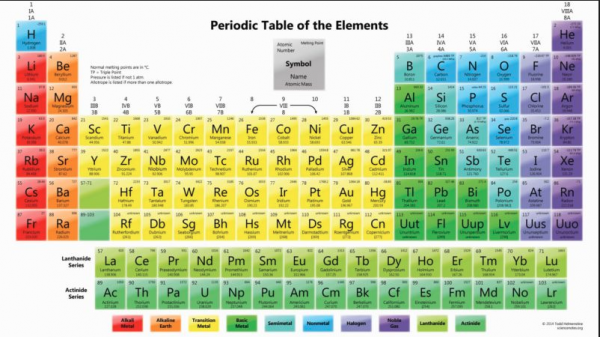

Identifying Halogen elements

The Halogens, or elements of group 17 of the periodic table, are Fluorine (F), Chlorine (Cl), Bromine (Br), Iodine (I) and Astate (AT). Halogens react with almost all elements of the periodic table and form ionic or covalent compounds that are often used as starting materials for the synthesis of other compounds, both inorganic and organic. Among the applications there is also the production of insulating material, used in transformers and, of course, in electrical cables.

Hazard of halogen elements in cables

Halogen elements, under certain conditions, can promote the spread of a fire and the gases released may cause serious damage to health. In excessive quantities, halogens have an immunosuppressant effect and weaken people’s cognitive and coordination skills.

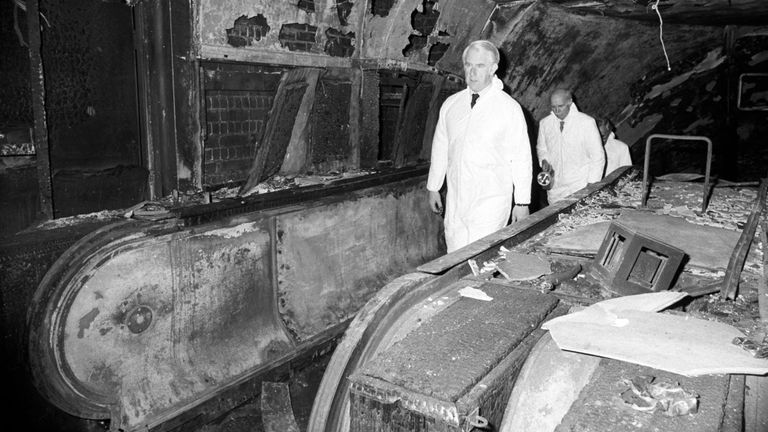

Historical notes on the hazardousness of halogen elements in electrical cables

According to the well-informed blog www.incore-cables.com, the key event that brought out the danger of halogen elements in power cables was the fire at Kings Cross station in London in 1987. In that catastrophe 32 people died and following investigations showed that the majority of deaths were due to the toxicity of gases and smoke, emitted by electric cables and inhaled by people, rather than to burns or open flames. That was the only time that people died in a fire in the London Tube.

Mandatory use of Halogen Free Cables

As a result of the fire at Kings Cross station, companies, cable installers and safety experts decided not to manufacture or use any more cables containing halogen elements. Soon came the obligation from the authorities that was extended not only to the London Tube and to other stations in general, but in all those buildings or infrastructure, public, private and high-density people, such as cinemas, shopping malls, hospitals, offices, etc..

Continuous development of Halogen Free cables

The obligation to install Halogen Free cables arisen after the metro accident reinforced the growing attention to safety and therefore, in the following years, La Triveneta Cavi began to produce the first LS0H (Trisecur) cables. The recent process of improving safety has seen the entry into force of the CPR Regulation (2017). Triveneta Cavi has already developed over 90 families of cables certified according to the CPR regulation and continues to develop new ones. Soon we will announce the launch of new Halogen Free cables that, completing our wide range, will add to all the others already in the catalog.

The brand La Triveneta Cavi was the protagonist of the recent Winter Olympics in South Korea 2018 which ended about a year ago.

Thanks to our Dubai partner Cleveland Cable, 250 Km of H07RN-F cable, manufactured at our La Triveneta Cavi facilities, were used to supply power to the entire Winter Olympic sports complex in Pyeongchang County, 180 Km from the capital Seoul.

Cleveland Cable recently told us about the success of such a big operation, starting with an auction that required a single cable supplier. The winner was our H07RN-F: it is a cable with excellent flexibility and good resistance to abrasion and tearing; it is resistant to weathering, grease and oil. It can be used both indoors and outdoors for mobile laying and ensures functioning down to -40°C, which is very important as these are winter sports games where snow and ice are the main element.

After the production that took place quickly and smoothly, the containers of material traveled directly from Italy to Dubai, where our partners worked with skill and precision in order to assemble cables and connectors under the instructions of their customers. The customer’s orders were very restrictive not only in the design phase but also as regards timing and shipments. The work table, in fact, required Cleveland Cable to supply the cable in very precise quantities and timescales and in steps. Furthermore, the budget and the estimated costs have always been respected, meeting the satisfaction of the final customer and, above all, the perfect success of all the installations of the 2018 Winter Olympics.

La Triveneta Cavi is very proud to have supplied its own product, designed and manufactured entirely in Italy for the realization of this great work of international scope and that has given us great visibility and prestige in our industry. We congratulate our partner Cleveland Cable and we look forward to the next major projects that await us in the world.

In addition to mechanical and electrical tests, cables are often also subjected to fire tests (the CPR Regulation is proof of this). The most common test is the flame retardancy. In fact, each cable sold must comply with certain resistance standards that vary according to the country of installation.

In the video we made at the laboratories of La Triveneta Cavi, we illustrate two ways to carry out the test, but according to different countries that require different requirements of the test: the one in force in the European Union, EN 60332-1-2 and the one used for North America, UL 2556.

Both have the same purpose but different methodology. In the European test EN 60332-1-2 the cable must be subjected to a continuous flame for a time determined according to the diameter of the cable. In the American test EN 60332-1-2 instead, the cable must undergo a series of cycles where the flame is applied and then removed.

Both cables tested have successfully passed the two tests; it is very interesting to visually observe the exceptional performance of the FG17, designed to withstand in these harsh conditions with a very low flame propagation.

Interview to Mr. Matteo Caldognetto, Sales Export Manager of La Triveneta Cavi.

In which markets are LTC cables present?

The export market represents more than 70% of LTC’s turnover, since we are present in over 40 Countries worldwide. Over the past 5 years we have seen a constant rising on the export sales with a 60% increase from 2013 till 2018. This was possible thanks to the efforts of all our Area Managers, back office operators and all other LTC departments.

What are the emerging areas for LTC market?

Germany remains the main European market but we are also focusing on other markets , like Scandinavia, Eastern countries and Russia. Worldwide, South America is facing a positive trend, last year we signed an important agreement with Mexico and we keep developing new business with other important dealers in those countries, as well as Africa and South East Asia.

How is the Made in Italy product perceived?

It is very positively perceived. We receive many inquiries from countries which are installing high quality Italian machinery and they also need Italian cables to have all the characteristics and certifications that our market guarantees.

What are your goals for the immediate future?

To confirm our very good sales in Europe and develop all other non- EU countries where we are not present yet but that require high quality products and a flawless service.

What’s this year’s most important news about La Triveneta Cavi?

LTC has invested several millions by realising a new automated Logistics Center that brought many advantages for the customers in terms of fast deliveries and precision. We are able to load and despatch 30 trucks per day and we have improved also the quality of the service through an automated management of the delivery.